|

|

|

|

#1 |

|

Участник

|

Sumit Potbhare: How Product arrive and Documentation | Standard Retail Inbound Needs | Approach to D365 for Commerce with Adv WH Mgmt

Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

============== Hi Guys, Welcome to another series where we will discuss the warehouse system requirements of direct to consumer and brick and mortar retailers where we will focus exclusively on Retail Warehouse Inbound needs and also we will take a look at what the requirements are for the inbound side of a Retail Warehouse. To look competent and sound credible in front of a warehouse manager, you need to be able to anticipate what they’re going to ask for when it comes to operating their warehouse. In my earlier post on Retail Warehouse Blueprint, we looked at how the setup of D365 F&O Warehouse Management can be divided into two types of configuration.

Let us take a look at the functional blueprint we drew in the previous post of the whole Retail Warehouse.  In this series, we’re going to be talk about the areas that are in the receiving dock as shaded in yellow.

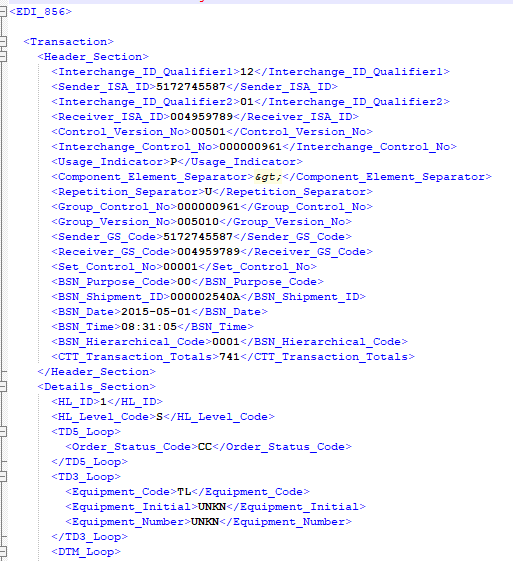

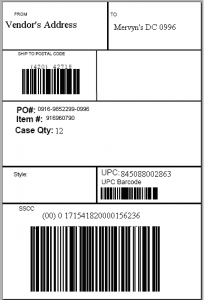

How do Retailer’s Get their Products? Let us talk about how retailers get their products or the products that they sell. And also look at how they arrive at the facility because this influences the process that goes on to get them into the building and the information that they get with that merchandise, telling them what is on a truck or inside a container because that also influences the process. Most retailers get their products from overseas vendors. And those vendors ship product to the retailer, usually via ocean freight. It takes somewhere between two to three weeks to get to the Retailer. Look at the ship where you can see the containers. Those containers are taken off that ship, placed on to a truck and driven to the Retail Warehouse.  When they get there, they’re opened up. And you’ll see inside them that everything has been packed really tightly into that container. There’s no pallets or anything like that. It’s just floor loaded cases that have been squeezed into a container, and that’s done because it’s expensive to ship this stuff so they want to use every cubic foot of capacity that they can. And this is done even for domestic transportation and for retailers that are in, India or China, because the cost of transportation is a lot higher than the cost of labor. So they want to spend the labor to pack out even domestic trailers in that fashion. Not necessarily that all the same SKUs will be together because it’s randomly distributed inside that container. When they get there, they’re opened up. And you’ll see inside them that everything has been packed really tightly into that container. There’s no pallets or anything like that. It’s just floor loaded cases that have been squeezed into a container, and that’s done because it’s expensive to ship this stuff so they want to use every cubic foot of capacity that they can. And this is done even for domestic transportation and for retailers that are in, India or China, because the cost of transportation is a lot higher than the cost of labor. So they want to spend the labor to pack out even domestic trailers in that fashion. Not necessarily that all the same SKUs will be together because it’s randomly distributed inside that container. 10% domestic products 10% domestic productsThen for domestic stuff, you’ll have, small parcel deliveries from local carriers. You’ll also have, less than truckload shipments, but that tends to be a smaller proportion of the overall freight. Then there are few products that always are really popular that are sold by a retailer. And usually, those items are so popular that they didn’t forecast exactly how many units they need to have. And they get exploded in their sales. And then the Retailer may ran out of them. Well, this situation happens to a lot of retailers all the time. What Documentation Comes with the Products? Now lets focus on to the information that comes with that merchandise shipped in by the vendor. This is important because this information is used by the receiving people to figure out what the goods are that they should be looking for. Usually there are different forms of information that accompany shipments that you need to be aware of.  Packing Slip: To start with, you’ve got to think about old school – paper. Many vendors, for years have been shipping paper documentation in the form of packing slips with the merchandise. These packing slips do nothing more than list the purchase order, the item and the quantity of a given item that you can expect to see on that trailer. So there will be one line on the packing slip for each item that’s being shipped in on that container or trailer. The information gets hand keyed into the WMS usually by a receiving clerk so that when the receiving process starts, the system already knows generally what SKUs are going to be on that trailer and how many units to expect of a given SKU so it can detect situations like when, the receiving associate attempts to receive a SKU that it’s not expecting on that trailer or a quantity that’s more than what it expected. Advance Shipment Notice (ASN) – PO Line wise: Now-a-days, vendors are getting smarter about communicating this information and they introduced the concept of advanced shipment notices or ASNs.  An advanced shipment notices are essentially electronic transactions or files that duplicate the information in a packing slip. And they list, the trailer number, the date it was shipped, the time it was shipped, the PO of each item on a trailer, the item itself, the quantity and the unit of measure that they’ve shipped. And you’ll get one record or line in the ASN for each distinct item on a trailer. And this is good information, because it eliminates that step of having to hand key the packing slips into the system to enter the receipt quantities before you start the receiving process.  Advance Shipment Notice (ASN) – Carton wise: This has been improved upon recently with what is now known as a Carton level ASN. And Carton level ASNs have more benefit compared to just PO line level ASNs. The carton level ASNs essentially are the same thing as a PO level ASN, except for every carton or case on that trailer, you will get one line in the ASN file. And that will show you the carton number, because every carton gets its own identifier, its own license plate that’s identified and applied to it by the vendor before it’s shipped. So this not only eliminate the data entry associated with setting up the expected receipt, but also the receiving process because instead of the receiving associate having to identify the item in a box, the quantity in a box and the PO in the box, all they have to do is scan that bar code. That carton license plate immediately tells the system what they are getting and what is inside that box and how many units are in that box. And that really expedites the process of receiving significantly. So these are the types of information that you can get along with an inbound shipment. I hope this blog was successful in laying the foundation to understand the Retail Inbound Needs and you get the understanding on how Retailers get their product and what document comes along so you can talk about during any D365 for Commerce implementation utilizing Advance Warehouse management. In our next blog, we are going to talk about what happens to merchandise after it is received in a Retail Warehouse. Feel free to reach out for any clarifications. If you like my blog posts then comment and subscribe to the blogs. Join 95 other followers Subscribe #RetailDAXing #D365Commerce Disclaimer: The information in the weblog is provided “AS IS”; with no warranties, and confers no rights. All blog entries and editorial comments are the opinions of the author. Credits: Microsoft Learn, Microsoft Docs Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

__________________

Расскажите о новых и интересных блогах по Microsoft Dynamics, напишите личное сообщение администратору. |

|

|